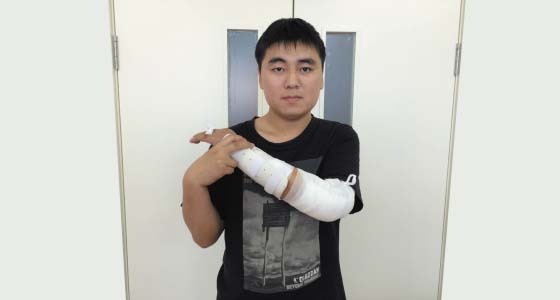

“看我的胳膊,可以向上伸到这儿了,几个月前我的左臂还只能成天端着,因为那时候没有肘关节。”在大连医科大学附属第二医院手足显微外科病房里,20岁的小伙子,此时充满了活力和自信,很难想象今年2月份遭遇意外后的几个月时间里,他曾经有多沮丧和颓废。

小李家住庄河,几个月前在工作中左前臂被数吨重的机器碾压,导致左侧上肢肘关节、腕关节毁损,虽然经当地医院抢救,保存了肢体,但肘关节却因损伤严重而缺失,当时他或者选择传统的关节融合,但将永远丧失绝大部分上肢的功能,小李和家属无法接受这一残酷的结局;若选择假体置换,小李肘部骨骼毁损严重,应用普通规格假体关节,很难实现骨骼的完全匹配……小李和家属多方求诊,慕名来到大医二院手足显微外科,梁海东副主任医师详细了解病情,检查后,决定应用目前较为先进的3D打印技术,为其量身打造一个肘关节,解决骨骼严重缺损难题。小李对这种治疗方式充满了期待。最终大医二院手足显微外科与吉林大学附属第二医院骨科、中国残联合作,成功为小李完成手术,这也是辽宁首例3D打印关节假体肘关节置换术。“小李入院后,童致虹主任带领手足外科的医疗团队通过三维CT扫描患者左上肢骨骼,将数据传送给北京一家假体制作厂家,厂家将数据输入电脑,3D打印技术通过数据扫描,打印出与患者等比例的骨骼模型,再利用钛粉逐层微量地根据患者实际数据做出嵌合假体,3D可精确到与患者原生骨骼一样的尺寸精度。”梁海东副主任医师告诉记者,3D打印技术已经成功应用于各学科中,在医学中的应用也逐渐取得突破。利用该技术可以为患者打造专属“个人”的肘关节,真正实现“私人订制”。因为3D打印关节就像为患者量身定做一般,可高度嵌合肢体,避免术中出现不匹配等问题,也可大大缩短手术时间,减少患者痛苦和手术风险。

仅仅半个月,经过骨骼三维重建,小李所匹配的肘关节假体经过反复调试终于成型。手术如期进行,手术过程中,梁海东医生实体检测,3D打印的假体和骨骼完全匹配,经过精准调试后,3D打印的人工肘关节假体顺利嵌合到肱骨和尺骨之间,解决了患者骨骼缺失过多的难题,同时比普通关节置入更加牢靠,手术时间缩短近一半时间。“这是我省首例3D打印技术运用到肘人工关节置换手术中,目前,在世界上采用3D打印技术置换肘关节仅在吉林大学完成一例。此次置换为世界上第二例患者。”梁海东医生告诉记者,未来假体置换手术,均应向“私人订制”方向努力,因为每个人骨头生长均不一致,都有细微的差别。假体精准度越高,其效果也就越好。为了追求更好的手术效果,未来将会有更多患者使用3d打印出来的假体。

2014-11-17 来源:光明网 记者:沈华

“Look at my arm, it can stretch up to here, a few months ago, I need to hold my left arm everyday, because there was no elbow joint.” At the Hospital of Dalian Medical University, the 20 years old man, Li Xian-hui are recovering back to be full of energy and confidence now, it is hard to imagine that in February this year, he was so depressed because of the accident.

A few months ago, Li’s left arm has been crushed by a heavy machine during work, his left upper limb elbow and wrist joint were seriously damaged. Although the local hospital rescued his limbs, but Li lost the function of his left arm because of the serious injury of elbow joint. Finaly, Li turned to Hospital of Dalian Medical University for further help. Dr. Liang Hai-dong did a profound study of Li’s elbow situation, the he made the decision to chose 3D printing technology to produce a tailor-made elbow joint for Li.

Dr. Liang Hai-dong got this case supported by the Second Hospital of Jilin University and CDPF. by the Second Hospital of Jilin University has 3D printed a titanium pelvic prosthesis for cancer survivor afflicted with bone metastases. Through 3D CT scan, they transmitted the data to a Beijing prosthesis manufacturer, then the manufacturer input the data into the computer, and built up the elbow joint 3D module. After that, they use the 3D printing technology to build up the titanium powder layer by layer according to elbow joint 3D module. Dr. Liang Hai-dong said that 3D printing technology has been successfully applied in various areas. Using this technology can create for patients with elbow joint exclusive “individual”, to avoid the problem of mismatch during operation, meanwhile greatly shorten the operation time, reduce the pain and the risk of surgery for the patients.

Only half a month, the elbow prosthesis has been produced. The operation was as scheduled, during the surgery, Dr. Liang Haidong successfully matched the 3D print prosthesis with bone, and through accurate debugging, the 3D print artificial elbow joint prosthesis well fitted to between the humerus and ulna. This finally solved the problem of the bone lost and artificial joint was even stronger than the regular elbow join. Meanwhile, they have shortened the operating time nearly by half. Dr. Liang Hai-dong said “This is my first time to apply the 3D printing technology to the elbow arthroplasty. At present, only the Second Hospital of Jilin University has done such kind of this case before. This is the second case we have done in our province.” Dr. Liang Haidong believe that the 3D print prosthesis is the trend due to the high flexibility, high accuracy of 3D printing technology. The higher accuracy of the prosthesis, the better results of the surgery, so there will be more hospitals and more patients adopt this technology.

2014-11-17 Source: Guangming Network. Reporter: Shen Hua