The metal 3D printing are getting more and more breakthrough on technology side. We see more and more companies such as Boeing, Airbus, Lockheed Martin, Honeywell, and Pratt & Whitney from aerospace industry pioneered the adoption of 3D printing technology in their application. We see Audi, BMW, Mercedes Benz, Jaguar, GM, Volkswagen, Toyota and Porsche from automotive industry are advancing 3D printing adoption from basic rapid prototyping purpose to advanced prototyping and exploration purpose. Meanwhile the metal materials that can be used in 3D printing have grown from Stainless Steel to Titanium, Aluminium and else.

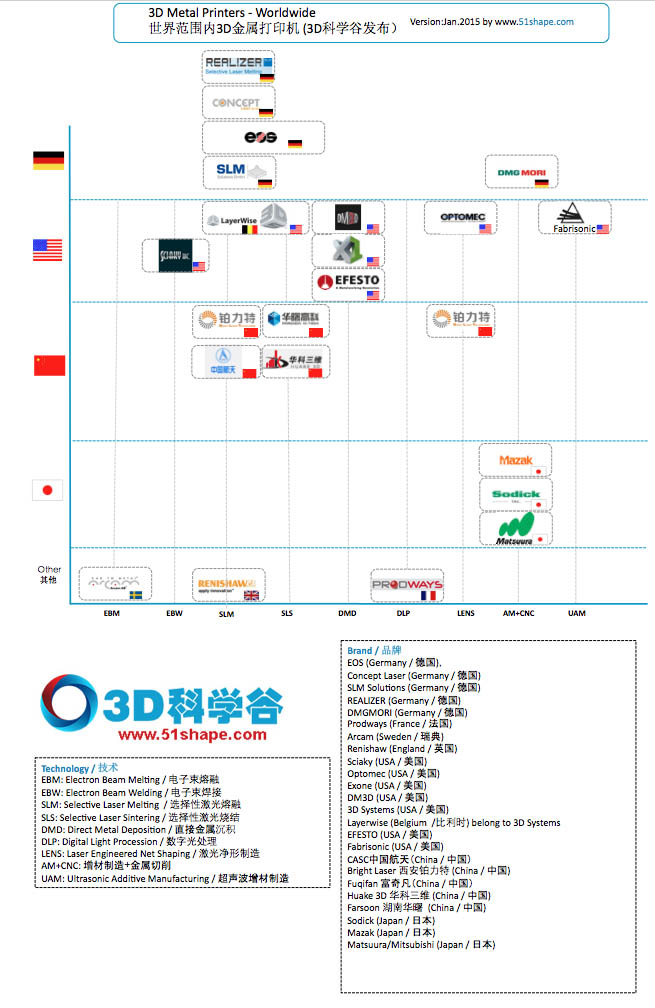

从食品打印,到生物打印,再到工业打印,3D打印真正的未来在哪里?无疑是金属打印,而从世界范围内看金属打印,无疑技术派系明显,可谓是一个国家制造业的大生态圈影响3D打印的小生态圈的起点,3D打印的小生态圈发展又折射出一个国家制造业的未来。下面是3D科学谷发布的世界范围内3D金属打印机企业矩阵。(关于国内企业介绍,详见一张图让你国外的合作伙伴了解中国3D打印产业集群)

// EBM电子束熔融技术

+ 瑞典 Arcam from Sweden

Arcam provides cost-efficient Additive Manufacturing solutions for production of metal components. The technology offers freedom in design combined with excellent material properties and high productivity. The company was founded in 1997 and is listed on NASDAQ Stockholm, Sweden.

Arcam is an innovative partner for manufacturing in the orthopedic implant and aerospace industries

瑞典Arcam AB公司发明了世界首台利用电子束来熔融金属粉末,并经计算机辅助设计的精密铸造成型机新设备。它能用于加工专为病人量身定做的植入手术所需的人工关节或其它精密部件等。该机器系利用电子束将钛金属的粉末在真空中加热至熔融,并在计算机辅助设计下精确成型(如制成钛膝关节、髋关节等等)。由于钛粉末在真空中熔融并成型,故可避免在空气中熔融所带来的氧化缺陷等质量事故。

// EBW电子束焊接技术

+ 美国 Sciaky from USA

Sciaky EBW process is the only large-scale, fully-programmable means of achieving near-net shape parts made of virtually any metal, including refractory metals, allowing manufacturers to save significant time and money over traditional manufacturing and rapid prototyping processes.

Sciaky 是一家成立于1939年位于美国芝加哥的专业焊接公司,电子束焊接是他们的专长,Sciaky 的 EBW 技术可制造的最大零件约为 5.8mx1.2mx1.2m,Sciaky 真正的领先之处在于超高打印速度,利用功率高达42千瓦的电子束枪,每小时可打印15-40磅的金属钛,而大多数竞争者仅能达到每小时5磅。就目前而言,电子束似乎是一种比激光更适合的金属3D打印能量源。相较于传统制造方式,使用 EBW 技术生产 F-35 的襟副翼翼梁除了成本更低外,寿命也更长,如果3000多架战机都使用这种技术制造部件,将可以节省数十亿美元的成本。然而航空业对于 Sciaky 而言只是一个开始,他们正在有针对性的对超过30个行业进行电子束金属3D打印技术的商业化。

// SLM 选择性激光熔融技术

+ 德国 EOS from Germany

In addition systems for Additive Manufacturing about both SLS and SLM technologies, the EOS solution portfolio comprises a wide range of materials; software and processes as well as extensive services and supplementary products.

EOS是德国著名的3D打印制造商。EOS 不仅为用户提供3D打印(增材制造)系统,还为用户提供制造解决方案及配套的打印材料,其塑料和金属的选择性激光烧结技术(sls)在市场上处于领先地位。可使用材料: 不锈钢材料、钴铬钼合金MP1、钴铬钼合金SP1、马氏体钢、钛合金、纯钛、超级合金IN718、铝合金。

+ 德国 Concept Laser from Germany

Both mould inserts with close-contour cooling and direct components for the jewellery, medical, dental, automotive and aerospace sectors can be fabricated with the Concept Laser LaserCUSING® layer construction process. With regard to mass production, the generative metal laser melting process can be used to implement new product ideas as well as metallic components which are subject to high mechanical/thermal loading.

在激光融化技术领域处于领先地位的是德国Concept Laser公司,该公司拥有LaserCUSING®技术专利。Concept Laser 主打的X系列1000R工业级3D打印平台,在构建尺寸在在激光熔融金属加工领域中是最大的。X系列3D打印设备可以处理各种各样的金属零部件,比如不锈钢、热作模具钢、钴-铬合金、镍基合金,活性粉末材料如铝、钛的合金,贵金属如金或银合金等。功能的多样化使得该产品能广泛用于航空航天、汽车、医疗和牙科、珠宝设计等行业。

+ 德国 SLM Solutions from Germany

SLM Solutions has established a solid reputation for innovation and industry service in SLM technology. SLM®-systems were the first to process reactive metal powders like Aluminum and also produce Titanium implants. The flexibility of SLM modular system, patented quad beam technology, and open system parameters are an ideal match to meet the strictest of industry requirements.

SLM Solutions是一家总部位于德国吕贝克的3D打印设备制造商,专注于选择性激光烧结(SLM)技术。公司前身是MTT技术集团德国吕贝克有限公司,2010年更名为SLM Solutions GmbH。而MMT隶属于英国老牌上市公司MCP技术,2000年推出SLM技术,2006年推出第一个铝、钛金属SLM 3D打印机。

主要产品:SLM 125、SLM 280、SLM 500系列选择性激光熔融——SLM 3D金属打印机,最大成型空间达到500x280x325mm,甚至可以装配两个1000W激光器。这种技术是采用高精度激光束连续照射包括钛、钢、铝、金在内的金属粉末,将其焊接成型的技术,而德国SLM Solutions在这一技术上有着多项专利,居于领先地位。其3D打印机已经应用于汽车、消费电子、科研、航空航天、工业制造、医疗等行业。

+ 德国ReaLizer from Germany

In 2004, Dr. Matthias Fockele founded ReaLizer GmbH, which focuses on the development and production of SLM™ machines for the manufacture of metal workpieces. In the SLM machines by ReaLizer, functional metal pieces mechanical properties equal the characteristics of conventionally produced workpieces.SLM technology can also be utilized to instantaneously produce customized human implants from medical 3-D data supplied by a CT or MRT, for example.

ReaLizer 2004年正式成立,注册专利为选择性激光熔融——Selective Laser Melting(SLM™),公司主要产品:SLM 50桌面型金属3D打印机,以及SLM 100和SLM 250工业级3D金属打印机。可使用材料:铁粉、钛、铝合金、钴铬合金、不锈钢以及其他定制材料

+ 英国雷尼绍公司(Renishaw) from the UK

Renishaw Additive manufacturing technologies encompass laser melting, vacuum casting and injection moulding technologies. Renishaw’s laser melting process is an emerging manufacturing technology with a presence in the medical (orthopaedics) industry as well as the aerospace and high technology engineering and electronics sectors.

雷尼绍的激光熔融 (Laser Melting)技术是使用高能光纤激光直接根据三维CAD生产高密度金属零件的创新型快速成型制造工艺。工件由各种微细金属粉末在严格控制的空气环境中经过熔化后制成,熔化制造时金属层厚度从20 μm到100 μm不等。广泛应用于航空航天、医疗和工业领域。可用材料:不锈钢316L和17-4PH、铝AlSi10Mg、钛Ti6Al4V、钴铬合金 (ASTM75)、铬镍铁合金718和625

+ 美国3D Systems Layerwise

LayerWise achieves a homogeneous micro structure with a relative density of up to 99.98%, for an increasing number of metals and alloys. Research shows that the mechanical properties are virtually the same as those of conventional metals.

3D Systems于2014年9月3日宣布购并金属3D打印公司LayerWise,为其公司增添另一生力军。LayerWise于2008年由鲁汶大学(University of Leuven)分立出来,是一家立基于比利时的金属3D打印公司,其服务以铸造金属模具或中小规模零件生产为主。LayerWise的直接金属3D打印机制造的金属零部件与传统金属零部件的密度比高达99.98%,与用常规方法制造的金属部件机械性能不相上下,而且单位重量显著减少。这些优势使得LayerWise在医疗设备、交通运输和精密仪器的垂直市场中发展迅速,因为对于这些市场中的客户来说,精度、强度和减轻重量是最重要。可用材料:不锈钢,铁、钛,铝和镍等。

+ 美国DM3D

DM3D offers a superior additive metal process for industry applications and solutions to problems encountered relating to wear surfaces or restoration and repair of components.DM3D technology is used in many fields such as:high value turbine engine components for aerospace- remanufacture or manufacturing new components such as bosses, flanges on engine casings etc. For Oil & Gas industry, DM3D Provides longer lasting downhole tooling.

DM3D是拥有十多年技术积累的3D打印公司,DM3D是一家以DMD为核心工艺,设计并制造3D打印设备的公司;同时利用自身设计制造的专业设备为客户提供残损零件修复、表面镀层强化、复杂零件打印制造等多种类型的金属3D打印服务。

+ 美国Exone from the USA

ExOne® revolutionary binder jetting technology can be applied to virtually any field or application — from aerospace to education, automotive to pumps and filtration. The 3D Printing process allows the creation of designs that were impossible using traditional manufacturing methods. Geometries can now be designed to enable cooling, heating, filtration, porting, venting, nested cores, spiral vents, volute shapes and integration of multiple components as well as to provide savings in material and weight for prototyping and short run production.

工业级3D打印机制造商ExOne以其打印尺寸全球最大砂材料3D打印机而知名。其实Exone在金属和玻璃材料的3D打印技术,以及激光微加工等方面也卓有成就。Exone公司还设置了8个全球性的制造中心,这些制造中心除了研发之外,还提供按需3D打印服务。3D打印材料的多样性表明了ExOne能够满足诸如航空航天、汽车、能源、铸造和医疗等领域内的3D打印应用需求。

+ 美国 EFESTO from the USA

EFESTO’s active markets include aerospace, defense, oil & gas, marine, tooling/die & mold, mining, construction and academia. Focus applications include repair/MRO, free-form fabrication of large and very large functional components, hybrid manufacturing, FGM applications and materials R&D.

大尺寸3D金属打印专家——EFESTO公司,最大的金属3D打印机EFESTO 557,该机器拥有一个1500×1500×2100毫米的超大构建室。EFESTO 557使用了EFESTO公司与RPM Innovations合作开发的激光金属沉积技术。它能够3D打印各种各样的金属材料,包括钴、镍、钢,以及铝和钛制成的合金材料。具体来说他们的技术是LMD(Laser Metal Deposition)技术,也被称为激光沉积技术(Laser Deposition Technology)是将金属粉末喷射到高功率激光器的聚焦激光束中,聚焦激光束熔化靶材料的表面,并产生基体材料的一小熔池,喷射的粉末被吸收入熔池,通过逐层堆积金属沉积即可用于构建或修理的金属部件,并适用于各种不同的应用。

// DLP 数字光处理技术

+ 法国 Prodways from France

Focusing on industrial companies, and including the dental and biomedical world, Prodways provides photosensitive resins, technical ceramics and metals, along with 3D printers that are all developed from their MOVINGLight technology, which is based on a combination of digital light processing and UVA LED high power.

Prodways 拥有MOVINGLight 专利,该专利结合了DLP 和UVA LED技术。L系列3D打印机使用光敏树脂为材料,而V系列使用复合材料。K20 Producer专为打印复合材料零部件设计。K20具备高粘度物料(膏状质地)的独特加工能力,可以3D打印复合材料零部件,尤其是陶瓷和金属材料。打印结果的密度非常高。

// LENS 激光净型制造

+ 美国 Optomec from the USA

The LENS and Aerosol Jet families of printers support a range of materials for metals, electronics and other applications, and are able to implement feature sizes never before possible. Optomec LENS technology leveraging high power and highly accurate laser technology to print a wide range of metals with new levels of precision, complexity and structural flexibility. Widely used for rapid prototyping and full-scale production of complex metal components in mil/aero markets, and the repair/replacement of parts requiring virtually any type of metal combination and finishing requirement. The Optomec LENS technology is competition to Xi’an Bright Laser’s LSF technology,

Optomec用来修复、电镀和快速生产多种高性能金属部件。LENS沉积系统使用高功率激光的能量,在瞬间直接将金属粉末变成结构层。LENS工艺过程发生在一个充满氩气的密室中,这里氧气含量低于10万分之一,以确保在金属沉积的时候不产生杂质。Optomec的专有粉末供给系统能够非常精确地向沉积系统添加所需要的金属粉末。当对象部件打印完成后,可以取出进行热处理,热等静压压制,机械加工,或以任何其他方式的处理。最后得到的全功能3维组件具有等同或优于使用锻造方式制造的部件的机械性能。

// AM+CNC 增材制造+金属切削

+ 日本松浦(Matsuura from Japan),代表机型:LUMEX Avance-25

A single machine platform integrating a fiber laser for state of the art metal sintering and a machining center for performing high accuracy, high speed milling. Lumex eliminates conventional processes, such as mold die splitting, electrical discharge processing, electrode designing, the fabrication of additional cooling water pipes, and assembly and adjustment work, thus greatly reducing the required time of mold die designing and processing.

LUMEX Avance-25金属3D打印机是世界上首个将金属激光烧结增材制造技术与和高速铣削工艺结合在一起的综合制造设备。GE公司的刈羽工厂,就使用的松浦3D打印机制造特殊的控制阀。

+ 日本沙迪克(Sodick from Japan),代表机型:OPM250L

Sodick has launched their additive manufacturing model – OPL 250 L since July 2014. They have applied 5 patents for this technology.

日本沙迪克公司(Sodick)2014年7月16日宣布开发出了使用金属材料加工的3D打印机“OPM250L”,于2014年10月开始销售。这款打印机采用金属光成型复合加工方法,将利用激光熔融凝固金属粉末的沉积成型与基于切削加工的精加工组合在一起。沙迪克已就这种加工技术与松下签署了授权协议,同时还在自主开发相关技术,已申请了5项专利。

+ 日本马扎克(Mazak from Japan),代表机型:Integrex i-400am

The INTEGREX i-400 is the latest generation multi-tasking machine providing versatility and performance in a state of the art designed package, that is both environmentally friendly and energy efficient.

Integrex i-400am采用的是激光烧结增材制造方法,光纤激光热源熔化金属粉末,熔覆头(即喷嘴)通过读取CAD定义的模型来熔融材料,该系统还可以加入不同类型的金属对象,可以修复现有的磨损或损坏的部件尤其象修复航空涡轮叶片,可以极大的节约成本。在数控机械加工方面,INTEGREX I-400AM提供了完整的5轴功能可以轻松地处理固态坯料或铸件、圆形零件,高异形零件和棱柱零件,以及那些经过增材制造处理之后的零件。

+ 德国 DMGMORI from Germany,代表机型:DMG Lasertec 65 3D

This innovative hybrid-solution combines the flexibility of the laser metal deposition process with the precision of the cutting process and therewith allows additive manufacturing in milling quality.Especially large workpieces with high stock removal volumes are now possible to be machined in an economical way.

LASERTEC 65通过粉末喷嘴进行激光堆焊与铣削加工共同构成的独特复合技术,为用户提供全新应用和几何形状可能。通过LASERTEC 65增材制造工艺,SAUER LASERTEC目前提供将激光堆焊与5轴铣削结合在一起的复合加工解决方案。此工艺通过金属粉末喷涂方式成形,这比在粉床中成形速度最高可快20倍。可实现3D轮廓,无需底层几何:例如加工法兰,加工圆锥,灵活切换激光加工与铣削加工(5轴+3D打印二合一),允许直接铣削最终零件中无法接近的加工部位。

// UAM 超声波增材制造

+ 德国 Fabrisonic from Germany

Ultrasonic Additive Manufacturing (UAM) is a revolutionary process technology that uses sound to merge layers of metal drawn from featureless foil stock. The process produces true metallurgical bonds with full density and works with a variety of metals.Many 3D printers measure material deposition in fractions of a cubic inch per hour. At these rates, parts are restricted to a small envelope that can be printed in a reasonable amount of time. Fabrisonic’s line of SonicLayer machines print from fifteen to thirty cubic inches per hour. This allows for much larger build volumes.

来自德国的Fabrisonic公司是一家以“超声波增材制造(UAM)”工艺为核心的工业金属3D打印机生产商。将金属层通过超声波增材制造工艺焊接在圆柱体形状的零件表面。这种工艺主要将应用在为各种圆柱体零件、各种轴、各种管的外表面添加贵金属层或者其他金属特征。

For the introduction of Chinese metal 3D printers, contact us at kitty.wang@51shape.com

图片看不清楚,有清楚的版本没?谢谢

换了清楚些的,谢谢您的意见